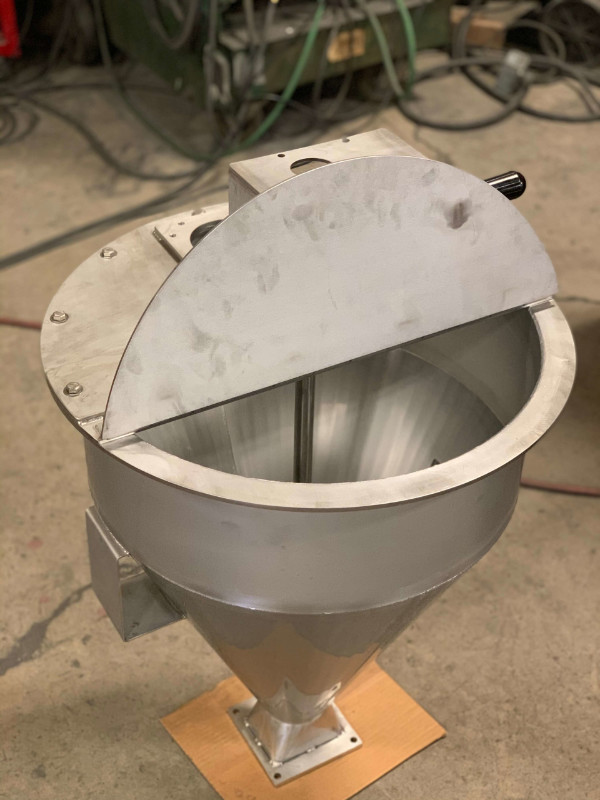

At Avon Lake Sheet Metal, our team fabricated and manufactured a 22.50” diameter x 31.25 tall extruder feed hopper for one of our clients. During the course of this project, our design and fabrication professionals utilized our extensive capabilities to meet the design specifications and requirements of this hopper.

Features of the Extruder Feed Hopper

The various characteristics and features of this hopper include an 11 gauge Type 304-2B stainless steel shell, in addition to:

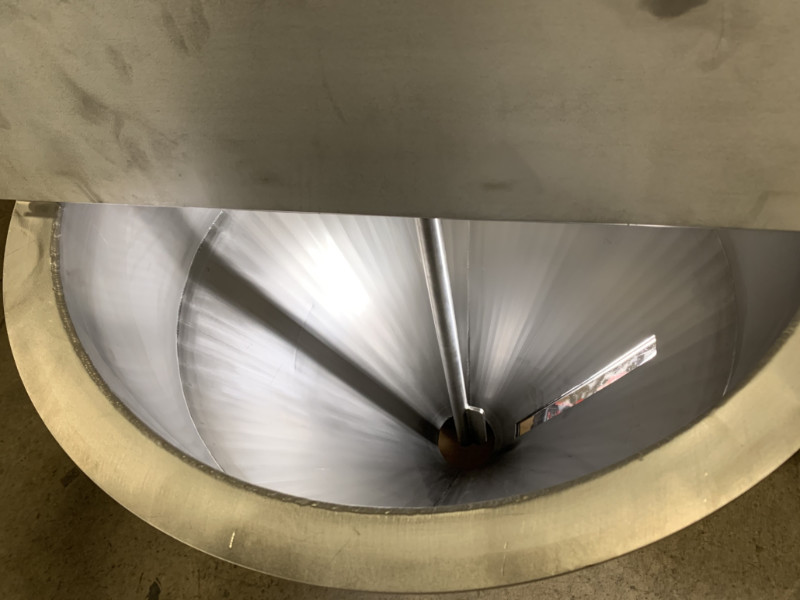

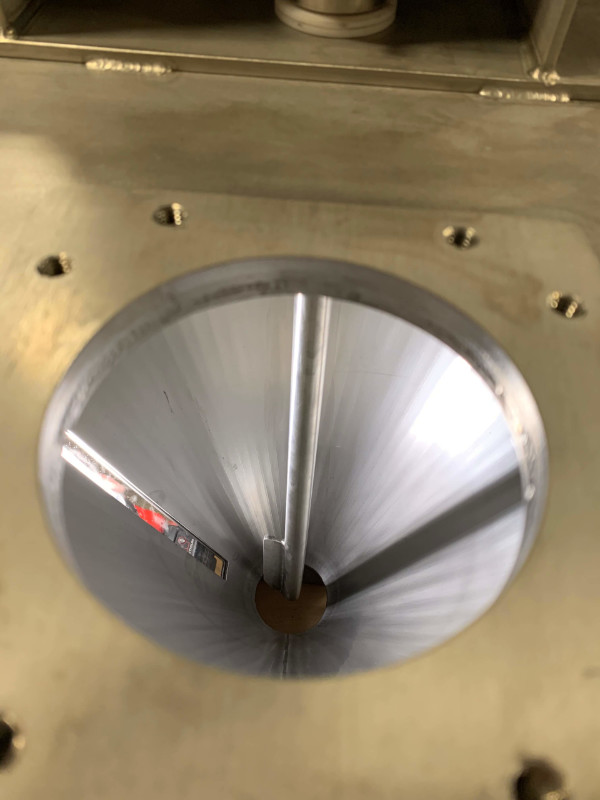

- TIG welded seams

- Outlet transition to match the customer’s extruder

- Inlet flange to match the customer’s loading system

- Rotating mixing paddle on SS shaft

- Outboard shaft bearings and motor mount

- Mounting bracket for motor control box

- Sight glass in sidewall

- Hinged opening lid

Design Processes Used

We developed the 3D model and AutoCAD drawings of this extruder feeder hopper for approval and construction. We understand the various design goals our customers have and implement our extensive design, fabrication, and manufacturing resources to meet the challenges of each project successfully. Our team is highly experienced at delivering a wide range of fabrication solutions. The results we achieved with the extruder feeder hopper project effectively demonstrate our capabilities.

As your dependable source for metal design and fabrication solutions, we not only handle a variety of fabrication challenges for our customers, but we also provide onsite plant installation and maintenance services.

Contact us today for information about how we can serve your industrial design and fabrication needs through our range of fabrication services.