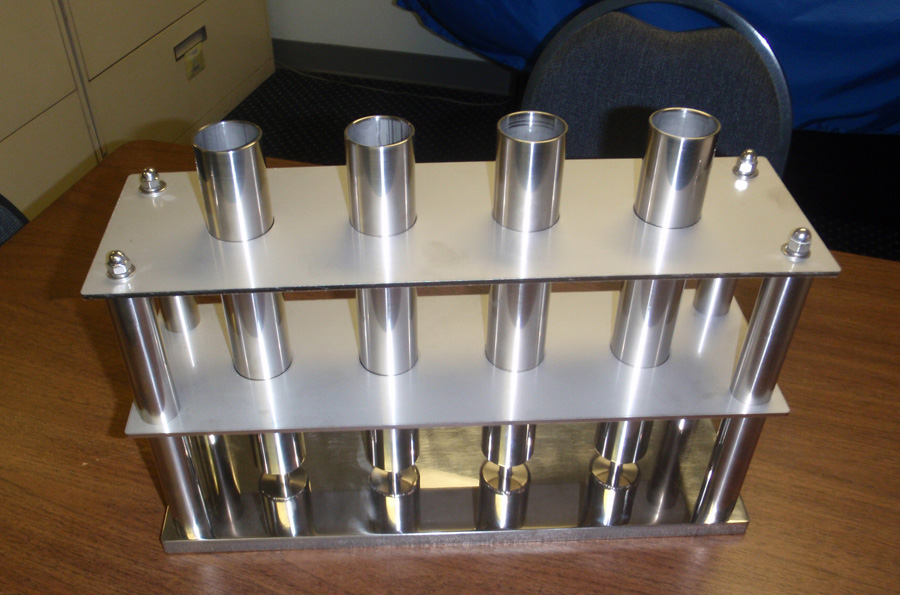

For almost 60 years, at Avon Lake Sheet Metal, we have been fabricating quality precision products for a wide range of applications. In the project highlighted here, we worked with a customer in the plastics industry to design and fabricate a custom laboratory testing tool. Known as a “deformation tester,” it is intended to act as a fixture to test various plastics for their deformation characteristics.

To simplify cleaning and allow for a long service life, the unit is composed of 304 stainless steel. The fabrication process utilized a number of our core competencies. Once the design was approved, raw material was precision laser cut, other parts were formed through turning, and then TIG welded. Once assembled, it was subject to dimensional inspection to validate the design criteria; once passed, the entire unit was polished to a mirror finish.

In the end, the tester met tolerances of ±0.015” and measured 16” in length, 5” in width, and 12” in height, with material thicknesses varying between 0.125” and 0.500”. To verify quality, the unit was again tested for dimensional accuracy as well as full functional testing.

One of the many benefits of doing business with us is our ability to act as a single source solution for metal fabrication services. In this case, the customer received a new tool quickly, in less than two weeks, which continues to perform and add value to their quality department.

To learn more about this project, or the processes used to manufacture it, see the table below or contact us directly.

| Capabilities Applied/Processes | Primary: Product Designing Laser Cutting Turning TIG Welding Secondary: Polishing |

| Overall Part Dimensions | Length: 16 in. Width: 5 in. Height: 12” Material Thickness: 0.125 – 0.500 in. |

| Tightest Tolerances | ± 0.015 in. |

| Material Used | 304 Stainless Steel |

| Material Finish | Mirror Finish on Base |

| Industry for Use | Plastics |

| In Process Testing / Inspection Performed | Dimensional Inspection, Functionality Testing |

| Delivery / Turnaround Time | 2 Weeks |

| Delivery Location | Avon Lake, OH |

| Standards Met | Customer Specifications |