Introduction

Fabricating a sheet metal box involves transforming a flat sheet of metal into a three-dimensional structure with sides and a bottom. This process requires precision, careful planning, and the use of various techniques. In this article, the experts at Avon Lake Sheet Metal will provide a high-level overview of the fabrication process for a sheet metal box, along with some common applications for the finished product.

Let’s Fabricate Sheet Metal! Beginning With Design and Material Selection

Before starting the fabrication process, a well-defined design and select the appropriate sheet metal material. The design should consider the box’s dimensions, shape, and desired functionality. The material selection depends on factors such as strength requirements, corrosion resistance, and aesthetic considerations. Standard sheet metal materials include steel, aluminum, and stainless steel.

Cutting and Shearing

The first step in fabricating a sheet metal box involves cutting the flat sheet of metal into the required size and shape. This can be accomplished using shearing techniques, such as manually operated shears or mechanized guillotine shears. Precision is essential to ensure accurate dimensions and clean edges.

Forming and Bending

After cutting the sheet metal, it is time to form and bend it into the shape of a box. This process involves using specialized machinery, such as press brakes or folding machines, to create precise bends along the edges. The number and complexity of bends depend on the design requirements. Accurate measurements, proper tooling, and skilled operators are crucial for achieving the desired shape.

Joining and Welding

The various components must be securely joined to assemble the sheet metal box. Welding is a common method used for this purpose, especially for steel and stainless steel boxes. Skilled welders use techniques such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding to fuse the metal parts together, creating strong and durable joints. Care must be taken to ensure proper penetration and to avoid warping or distortion of the box during the welding process.

Finishing and Surface Treatment

Once the box is fabricated and assembled, surface finishing and treatment can be applied to enhance its appearance and durability. This may involve processes such as deburring, grinding, polishing, and applying protective coatings. Deburring removes any sharp edges or burrs, while polishing provides a smooth and aesthetically pleasing finish. Coatings, such as powder coating or electroplating, can offer corrosion resistance and improve the box’s longevity.

Applications of Sheet Metal Boxes

Sheet metal boxes find application in various industries due to their versatility and durability. Here are some common applications:

Electronics and Telecommunications: Sheet metal boxes are used to house electronic components, circuit boards, and telecommunications equipment. They protect against dust, moisture, and electromagnetic interference while allowing easy access for maintenance and repairs.

Electrical Enclosures: Sheet metal boxes enclose electrical panels, junction boxes, and control cabinets. They ensure electrical systems’ safety and proper functioning by protecting sensitive components from environmental factors and preventing unauthorized access.

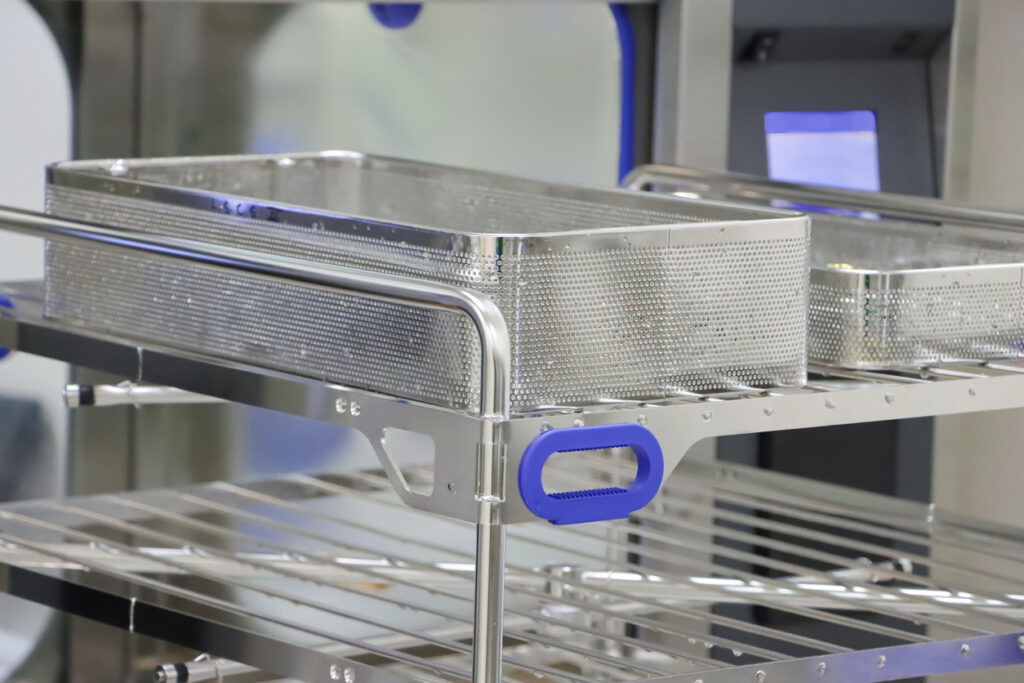

Industrial Storage and Transport: Sheet metal boxes are utilized for storage, handling, and transport of goods in warehouses, factories, and logistics operations. They offer durability, stackability, and protection for items such as tools, parts, and products.

Automotive and Aerospace: Sheet metal boxes are found in vehicle components, such as battery enclosures, engine compartments, and cargo areas. The aerospace industry uses them for avionics enclosures, equipment storage, and aircraft cargo holds.

Custom Applications: Sheet metal boxes can be customized to meet specific requirements, making them suitable for unique applications in various industries. Examples include specialized enclosures for medical equipment, instrument cases for musicians, display cases for retail environments, and even art installations. The flexibility of sheet metal fabrication allows for creative and tailored solutions to accommodate diverse needs.

HVAC and Ductwork: Sheet metal boxes are commonly used in heating, ventilation, and air conditioning (HVAC) systems for housing components like air handlers, ductwork transitions, and plenums. These boxes ensure proper airflow and efficient system operation and facilitate maintenance and access for service technicians.

Outdoor Cabinets and Enclosures: Sheet metal boxes with weather-resistant coatings are widely used for outdoor applications. They protect electrical equipment, telecommunications infrastructure, and outdoor appliances. These boxes are designed to withstand harsh weather conditions, corrosion, and vandalism.

Conclusion

Fabricating a sheet metal box requires careful planning, precise cutting, skilled forming and bending, accurate joining, and meticulous finishing. The process involves transforming a flat metal sheet into a functional and robust three-dimensional structure. Sheet metal boxes find application in various industries, including electronics, electrical systems, industrial storage, automotive, aerospace, and custom applications. Their versatility, durability, and customizable nature make them ideal for housing and protecting components, equipment, and goods. By understanding the fabrication process and exploring the wide range of applications, clients can efficiently leverage sheet metal boxes to meet their specific needs.

Remember, sheet metal fabrication requires expertise and specialized equipment. Consulting with a reputable sheet metal manufacturing company like Avon Lake Sheet Metal can ensure high-quality results and tailored solutions for your unique requirements. Give us a call today at 440-933-3505.